Because fish deserve safe and first-class travel, too

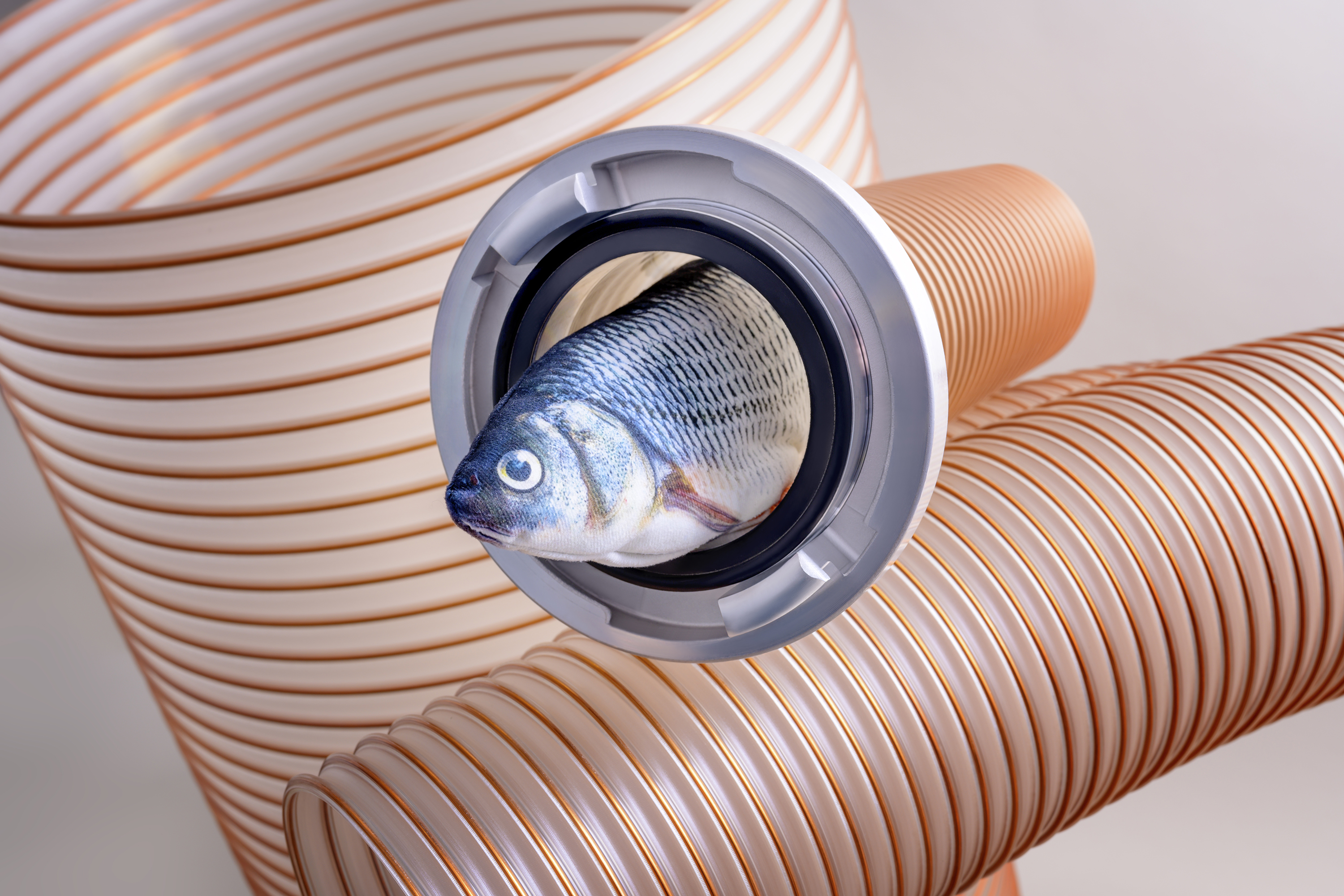

Caption: Master-PUR H FishTec. Profile extruded PU transport hoses in different diameters with metal spiral and a fish and with connecting element

Master-PUR H FishTec, represents the future of fish transportation in the fishing industry

The seafood industry faces unique challenges, especially when it comes to transporting fish and seafood. Efficient and safe solutions are paramount to ensure the quality and integrity of your cargo.

Masterflex SE has worked hard to develop an innovative solution specifically tailored to the needs of the seafood industry. The engineering service team from Gelsenkirchen, Germany, is proud to present the new Master-PUR H FishTec hose – a technological masterpiece specially developed for the transport of fish such as salmon.

Masterflex, the German and internationally renowned world market leader for hose and connection systems, says: “Welcome on board for customized plastic hoses for the fishing industry. Join us in the future of fish transportation, where safety, efficiency and quality are paramount”.

A fisherman with the Master-PUR H FishTec hoses on his shoulders, which have been developed and certified for use in the fishing industry

Safety and efficiency in fish transport

The Master-PUR H FishTec is made of high-quality polyurethane and is characterised by its robustness and durability. Its smooth inner surface ensures optimum flow speed and prevents the formation of deposits. The hose is also resistant to UV radiation, ozone and many chemicals. This special transport hose has been certified according to the strict Norwegian standard NS 9416:2013 to ensure that no fish are lost during transport. What’s more, the hose is food-compliant and certified for the fishing segment.

The importance of choosing the right hose for the fishing industry should not be underestimated. Hoses are often seen as secondary components, but their manoeuvrability makes the operation of machines and systems really flexible. And in many places, only hose lines can be used. However, not every hose is suitable for transporting food or fish under difficult operating conditions. So those who also rely on certified quality for components are playing it safe.

There are different requirements for hose systems for the specific handling of fish and seafood.The fish itself is firm and a very sensitive material to transport. The salt water is tough and the environment is harsh.

In addition to the right material, therefore, a food-grade hose must have a smooth, easy-to-clean inner surface to prevent the spread of microorganisms. Not only is the material important, but also the hose geometry, pressure resistance, robustness, aging resistance, and abrasion resistance. A food-grade hose must also be easy to clean, sometimes with highly alkaline detergents, so the material selected must be inert.

Outstanding material properties certified under real conditions

In order to meet the very demanding Norwegian standard NS 9416:2013, the Master-PUR H FishTec was subjected to real conditions as part of the hose certification at the Masterflex Quality Assurance Center in Gelsenkirchen with Olve Vangdal (Lead Auditor/DNV) from Norway. The hose was filled with water up to the working pressure, then the hose wall was struck with a sharp object to create a hole or tear. This live simulation confirmed the excellent material properties of the hose and its high resistance to stress cracking, which in real -world operations ensures that no fish can escape or get injured on sharp edges.

Meeting situation in the meeting room. With Masterflex Group Global Key Account Manager Food & Pharma (left) and Head of Sector Management Industrial Solutions Torsten Gebhardt (centre) A customer on the right

Internal smoothness and flexibility for higher productivity

Master-PUR H FishTec not only impresses with its excellent internal material properties, but also with its flexibility. Different sizes are available to meet the individual requirements of systems or designs. Even sprues are optional.

In addition to its absolutely remarkable inner smoothness, the special Masterflex coating should be mentioned here. Masterflex manufactures the hoses in this way without reducing the actual inner diameter. In addition, the production system does not create any impact edges that could injure fish, such as salmon, during transport. This increases productivity for the end user and ensures that your cargo reaches its destination in the best possible condition.

Fishing for the perfect hose connector

When abrasive media, powders, liquids or even marine animals and fish are fed through food hoses, the right connection technology is also important. In particular, screwable and flexible connectors support the production and cleaning process. If the connection to a pipe or hose is not a perfect fit, the result is an uneven transition. If the clamp connections are not optimised, these edges can not only injure the fish and reduce its value as mentioned above, but they can also be a reason for material residues to accumulate and become so stubborn that they can lead to bacterial contamination.

Hose systems support the sustainability of the fish farming industry

Masterflex uses the patented and wear-warning AMPIUS® hose management system at the customer’s request to promote sustainability in the fish farming industry. Our hoses and hose systems enable efficient fish farming that prevents overfishing of the oceans. Early warnings about the condition of the hoses protect the fish, safeguard your process, and help conserve natural fishing grounds.

Master-PUR H FishTec. Profile extruded PU transport hoses in different diameters with metal spiral. Medium-duty, good flexibility, microbe-resistant and hydrolysis-resistant, certified to NS 9416:2013. Approved for direct food contact in accordance with EU Directive 1935/2004, 10/2011 and its latest amending directives. Material complies with the food regulation FDA 21 CFR § 177.2600, certified according to NS 9416:2013 and with connecting element

Master-PUR H FishTec makes waves in the industry

Don’t miss the opportunity to optimise your transport processes and improve the quality of your cargo. Order your Master-PUR H FishTec hose today and experience the future of transportation in the seafood industry. For more information and expert advice, visit our website or make an appointment with our team of experts. Our Key Account Manager, Food and Pharma Marc-Julian Ott, will be happy to answer all your questions and concerns. Your success in the fishing industry is important to us.

The Masterflex Group is the listed specialist for the development and manufacture of sophisticated connector and hose systems made of high-performance plastics and fabrics.

Six strong corporate brands and 14 operating subsidiaries worldwide make up the Masterflex Group. Our products and solutions ensure demanding and essential functions in high-tech sectors such as aerospace, medical technology, mechanical and plant engineering, the chemical industry, food and pharmaceutical technology and other important industries. In addition, the Masterflex Group also offers consulting and order-related development services for hoses and connector systems as part of its engineering services.

www.masterflex.de/en/