Tired of scrubbing your probes?

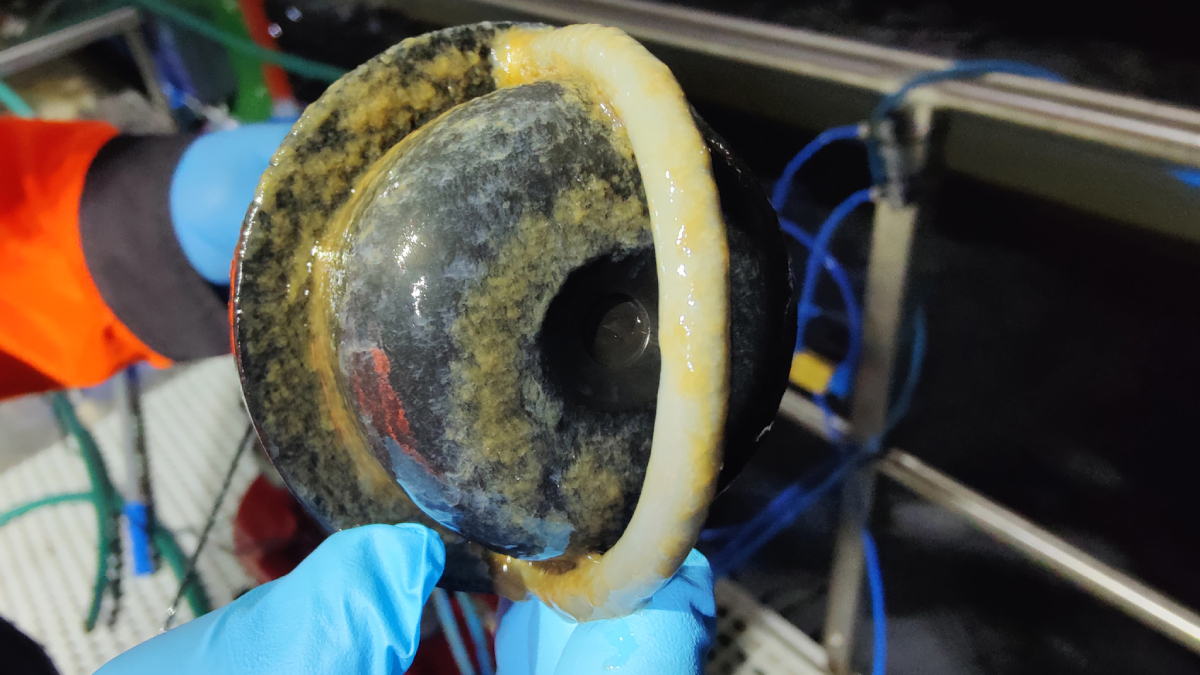

No fouling at the probe’s measurement point, only on areas that don’t impact performance

Please Login/register for FREE to continue reading Fish Farmer

Your FREE registration gives you access to all our content: news and feature articles, regular and special guest columnists, Fish Farmer Magazine e-editions, yearbooks, archives, videos and more

or if you are already registered

Use the Login Box Below

(Can't remember your password? Click Here to reset your password

Deckhand (Argyll Net Washer) - Mowi Scotland

Argyll & Bute£28,258 to £31,648 per annum

Freshwater Advanced Husbandry Operator - Landcatch Ltd

OrmsarySalary On Application

HGV Driver - Mowi Scotland

RosythSalary On Application

Hygiene Operative - Night - Bakkafrost Scotland Limited

Cairndow£33,273.52 per annum

HR Business Partner - Bakkafrost Scotland Limited

Cairndow£40,000 to £50,000 per annum