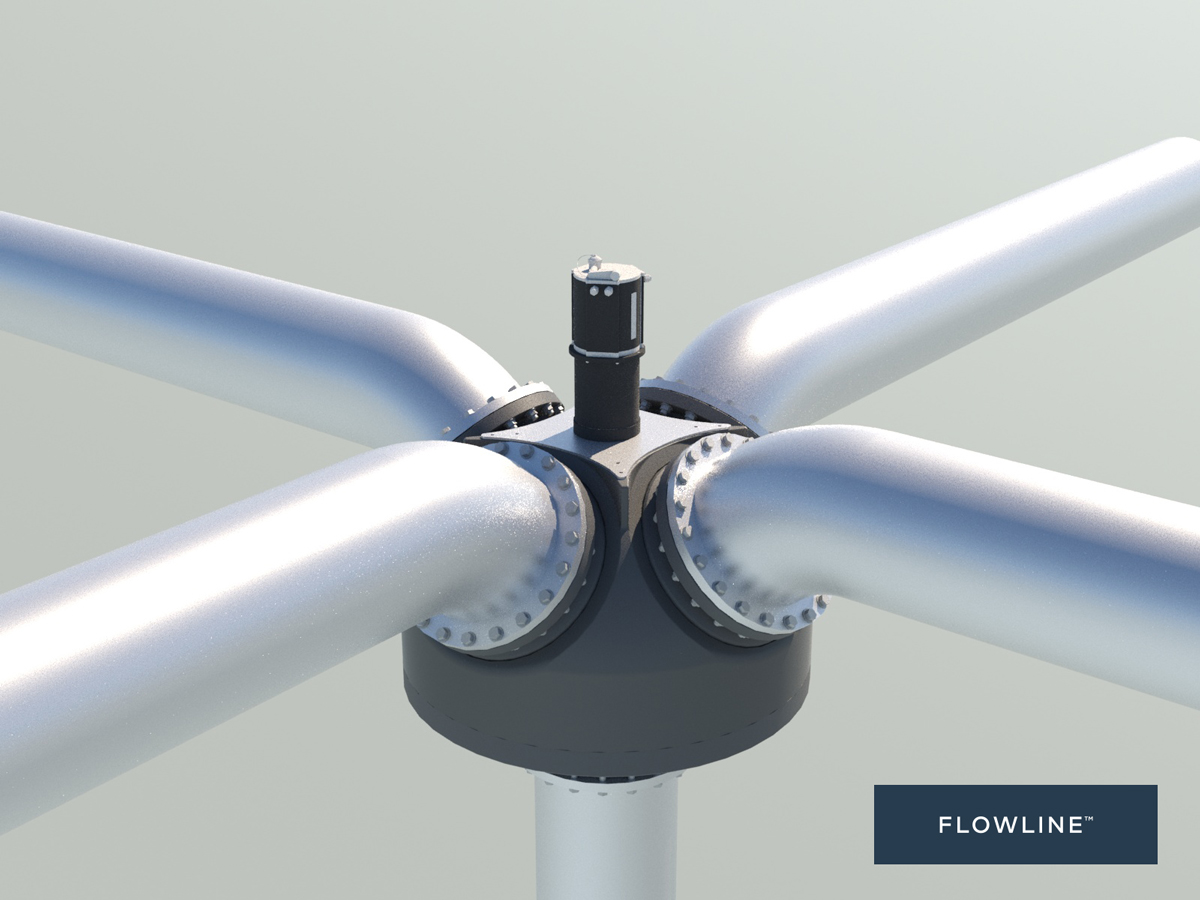

Developers say new valve system will help fish welfare

Simpler, safer handling is now possible, say the Norwegian developers of a new system for transferring fish, and the system is being installed in what will be the world’s largest wellboat.

Cflow’s new system, Flowline, uses a stronger, more durable type of plastic than that normally used in fish handling, and it also makes use of a four-outlet valve instead of the typical three-way valve.

The system is being built into the wellboat Gåsø Høvding, which is under construction at the Sefine Shipyard in Turkey, commissioned by Frøy Rederi.

Gunnar Hoff, Cflow CMO said: “\”We chose an interdisciplinary approach to the development process with our focus being on increased fish welfare. Experts from Norwegian wellboat companies, biologists, and suppliers of cleaning systems have all contributed to the fine-tuning of all functions. Together, we have developed Flowline, a forward-looking concept that will both simplify and improve fish handling.\”

Tor Andre Rønning, Cflow senior engineer explained that the philosophy behind Flowline was based on prioritising the main functions of the fish handling system: reducing bends, valves, lifting height and piping to a minimum.

He said: “The current modern fish handling systems, both on land and at sea, have strict requirements for flexibility and options. Cflow\’s new Flowline concept naturally meets both these requirements and those for gentleness.\”

To simplify cleaning and maintenance, the Flowline valves have been given several ports for cleaning, flushing and draining. Surfaces are smooth with no pores or scratches, in order to avoid conditions for bacterial growth.

Flowline was developed in cooperation with Astorplast AS in Fosnavåg, Norway.